Optomec redefines layered production. This technology from Optomec includes printers, software, materials and application expertise, and the product lifecycle that makes it possible to produce components and features that were not previously possible.

The two technologies offered by Optomec are Aeroseol Jet and LENS precision, increasing flexibility and efficiency. Investing in a successful development history and $ 30 million in product development, Optomec has worked with leading industrial companies and research organizations in various markets to deliver the promise of 3D printing. Optomec systems are used throughout the product lifecycle to reduce the size and cost of electronic devices, increase the efficiency of machines that produce alternative energy sources, extend the life of high-value aviation components, produce wear-resistant medical devices and make industry.

Discover what you can do:

- Propellers, Blisters

- Alternative Energy Components

- Metal Parts with Complex Geometry

- Carbon Nanotube (CNT) Thin Film Transistors

- Mobile device antennas manufactured with 3D printer

- Displays

- and much more

Shape the Future with Optomec Layered Production Solutions

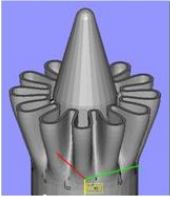

LENS® technology; ”Laser Engineered Net Shaping inin stands for Laser Shaping. It is a proven industrial layer production system for repair, modification and manufacturing.

3D CAD Model

Production with LENS Technology

Final Product

Key Features

- Great working volumes – ideal for blisters (discs and palettes used in turbine engines), propellers and shafts

- 5-axis motion – rotary and complex repairs

- Closed-loop controls – Precise process control

- IPG Fiber Lasers – Low cost of ownership

- Full software package – Quickly creates tool paths

- Full atmosphere control – Superior material quality

- Commonly used materials – Inconal alloys, stainless steel, Titanium alloys, Aluminum Alloys

- Applications

- Hybrid Production

- Advanced Product Development

- Repair of worn parts

- Repair of incorrectly machined parts

- Tool modification for reuse

Uygulamalar

- Hybrid Production

- Advanced Product Development

- Repair of worn parts

- Repair of incorrectly machined parts

- Tool modification for reuse

Aerosol Jet® Technology

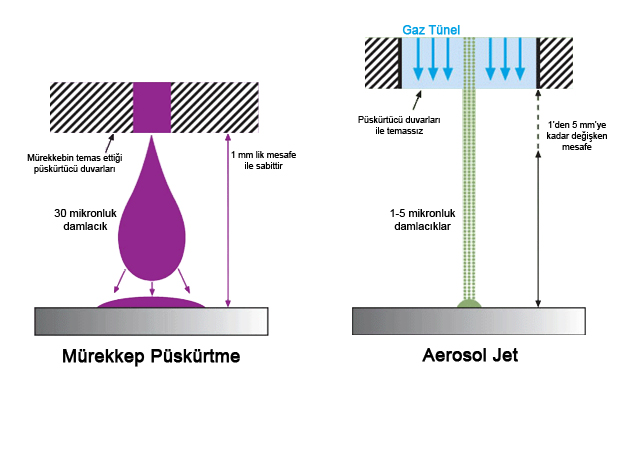

Aerosol Jet systems have a unique ability to print on almost all substrates with their very precise details, electronic, structural and biological patterns. Some compare the Aerosol Jet Technology to the inkjet method, but the patented process is completely different. The material to be sprayed is atomized by an ultrasonic and / or pneumatic system. The droplet dimensions of the material can then be further reduced by using a ları virtual impactor Daha. The material jet formed in the final stage is aerodynamically focused using the gas in the agglomerate head and the agglomeration is carried out. Technology can work with a variety of materials such as Silver, Copper, Nickel, Polymer and Teflon. With this technology, it is possible to produce electronic products as well as to circuit the surface of a 3D part.

Advantages of Aerosol Jet Technology

- Sizes up to 10 microns

- Stacking thin layer from 100 nm

- Many material options

- Material viscosities between 1 and 1,000 cP

- Nanomaterial material

- Applicability to non-planar surfaces

- Low temperature workability